System configuration of furnace temperature tester :

1, one instrument host.

2, thermocouple (according to the instrument channel number configuration).

3, one CD (including instructions, software, etc.)

4, one data line.

5. One roll of high temperature tape.

6. One insulated box (box).

7, a er manual.

8, a pair of protective gloves.

One, Furnace temperature tester Host selection

选择Furnace temperature tester主机时请确认被测工件需要几个温度测试点,几个温度测试点也就是仪器的通道数量,通 道数越多,测出来的温度曲线会分析得越.常用通道数:6通道、8通道.

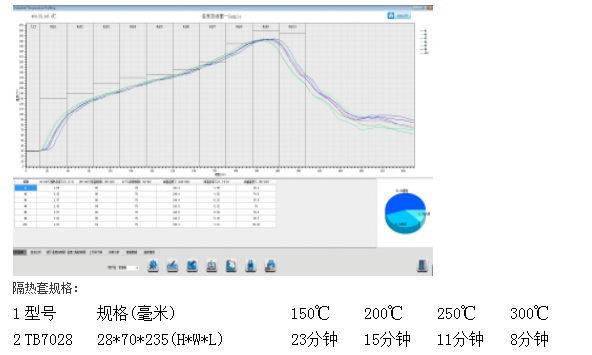

Two, 隔热箱配备:300度10分钟

Pre-sale communication: Please confirm the size of the furnace when selecting the insulated box, lest the insulated box is too high, resulting in unable to enter the furnace, and pre-sale technical communication is needed when the size of the furnace is too small

Insulated box Features: The insulated box of our furnace temperature tracker uses the same insulation technology as the "black box" on aircraft to withstand the harshest environments. The insulated box is microinsulated, protected by a premium stainless steel housing and modified to have a strong snap switch that is easy to use. Strong and lightweight, these insulated boxes can withstand high-temperature processes with multiple runs and have an extremely long service life Heat insulation box function: protect the instrument host in the furnace test will not be burned by high temperature

Special requirements can be customized by calling.

Three thermocouple equipped: SMPW-K-M TT-K-30-0.5M (0.5M) high temperature resistance 260 degrees

All K-type thermocouple wires and plugs meet the highest standards, thus ensuring the highest level of accuracy; Our thermocouple supplier is the world's top OMEGA company, the precision of thermocouple is 0.01 degree

Product name: furnace temperature recorder

Product model: JK60i

Number of test points: 6

Product brand: jinko, Chinese name: Jinke

Application: Used for temperature measurement of various heating or refrigeration equipment. Long-term temperature monitoring. Temperature curve mapping and temperature data analysis, etc

Scope of application: SMT electronic manufacturing. Metallurgy. Heat treatment. Baking paint coating. Brazing.IR. Tunnel furnace, etc. all the industries that require temperature monitoring or measurement

Product Features:

1: small size, powerful function, design service life of more than 10 years

2: High measurement accuracy /-0.5℃, fast speed, the fastest 0.01 seconds/time, easy to meet any challenges in the field of temperature measurement

3: High-speed USB interface communication and charging integrated, permanent no additional charging

4:3 kinds of trigger start mode,4 kinds of trigger stop mode can be optimized at will, to achieve intelligent start and stop, without manual intervention

5:1200 mA Polymer rechargeable Battery Powered

6: Up to 100 groups of more than curve overlap analysis

7: A maximum of 255 groups of temperature curve data can be saved (optional)

8: Complete firmware information prompt, users can at any time to check the use of the instrument records. Status and hardware configuration information

9: Intelligent PWI index analysis

10: Automatic curve optimization function

11: Instrument time can be set or calibrated with the computer synchronization

12: Powerful curve editing function

Product specification:

Temperature curve analysis setting function (data analysis report) :

1, reflux furnace and wave furnace temperature area set temperature and transport speed

2. Location name of temperature sampling point and PCB diagram

3, the time between two temperature values

4, the slope between the two temperature values

5, the slope between the two time points

6, beyond the specified temperature time

7. Maximum temperature and temperature at any point in time

8. Horizontal temperature line, vertical time line and the time between time

9, mesh editing refinement and curve scaling disy

10. Simulation curve function, process optimization, test date and time

11. Input company name, product name and remarks information

12. Select the printing direction (landscape and portrait)

13. The temperature data report can be exported to Excel for editing

14, insert the picture function, so that the temperature test point location at a glance

15, call multiple groups of temperature curves for comparison

16, real-time monitoring and instrument recording two working modes

17, manual clearing and software clearing instrument memory data

18, manual, specified time, specified temperature three startup modes